The increasing global concern over plastic waste has prompted innovative solutions, particularly in the construction industry. Waste plastics can be effectively converted into modifiers for asphalt, enhancing its performance while promoting sustainability. This article outlines the process of converting waste plastics into usable modifiers for asphalt mixing plants, focusing on the benefits and methodologies involved.

The Process of Plastic Conversion

Converting waste plastics into asphalt modifiers involves several key steps, starting with collection and sorting. Plastics, particularly polyethylene (PE) and polypropylene (PP), are commonly used due to their favorable properties. Once collected, these plastics need to be cleaned and sorted to remove contaminants, ensuring a high-quality end product.

After sorting, the plastics are subjected to a process called thermal degradation. This involves heating the plastics to a specific temperature where they break down into smaller molecules, creating a liquid or semi-liquid form. This process can be performed in various types of reactors, including batch or continuous systems, depending on the scale of operation. The resultant material can then be blended with traditional asphalt to create a modified mix.

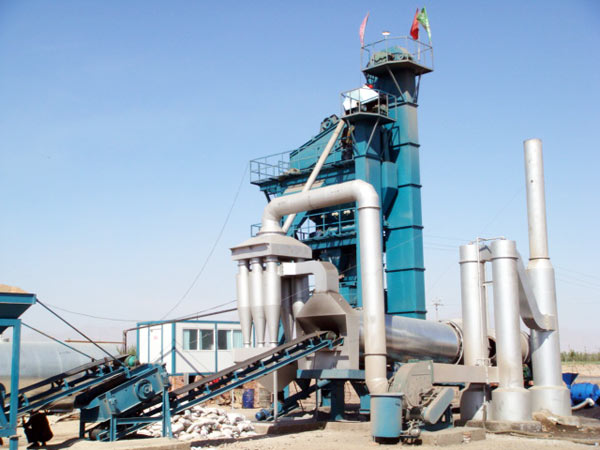

In stationary asphalt mixing plants, operators can directly incorporate these plastic-derived modifiers into the asphalt binder. This integration enhances the performance of the asphalt, increasing its resistance to cracking and deformation. Mobile asphalt plants can also benefit from this process, allowing for on-site recycling of waste plastics into valuable materials.

Benefits of Using Plastic Modifiers in Asphalt

The incorporation of plastic modifiers into asphalt mixtures offers multiple benefits. Primarily, it enhances the durability and longevity of the asphalt. The plastic fibers improve the mixture's elasticity, making it more resistant to temperature fluctuations and heavy traffic loads. This is particularly advantageous for high-traffic areas, where traditional asphalt may degrade more quickly.

Additionally, using recycled plastics reduces the amount of waste sent to landfills, contributing to a more sustainable approach in construction. This not only supports environmental goals but can also improve the public image of construction companies committed to sustainability efforts. Furthermore, utilizing waste plastics can potentially lower material costs for asphalt mixing plants, as it reduces dependence on virgin materials.

Quality Control and Performance Monitoring

To ensure the effectiveness of the plastic modifiers, rigorous quality control measures are essential. Asphalt mixing plants must conduct thorough testing on the modified asphalt to assess its performance characteristics, such as viscosity, adhesion, and resistance to aging. This can include laboratory tests as well as field evaluations to monitor the long-term performance of the asphalt in real-world conditions.

Regular monitoring of the mixing process is also crucial. Operators should be trained to manage the integration of plastic modifiers effectively, ensuring that the mixture achieves the desired properties. For instance, in batch mix asphalt plants, precise control over the mixing time and temperature is necessary to achieve optimal results.

By implementing these quality control measures, asphalt producers can maximize the benefits of using waste plastics as modifiers, ensuring that the final product meets industry standards and customer expectations.

Conclusion

In conclusion, the conversion of waste plastics into modifiers for asphalt presents an innovative solution to both waste management and performance enhancement in asphalt production. Through careful collection, thermal degradation, and integration into asphalt mixtures, waste plastics can significantly improve the durability and sustainability of asphalt products.

As the demand for eco-friendly construction materials continues to grow, asphalt mixing plants—whether fixed, mobile, or mini—should consider incorporating these practices. By doing so, they not only contribute to a sustainable future but also enhance the quality and performance of their asphalt products, ultimately benefiting the entire construction industry.